Can a Plumber Fix a Boiler?

The easiest way to book quality trades

When your boiler breaks down on a freezing winter morning and you're facing the prospect of cold showers and no heating, the question of who to call becomes critical. Should you contact a plumber or do you need a Gas Safe registered engineer? The answer could save you hundreds of pounds and hours of frustration. Check out our FREE Plumbing Cost Calculator.

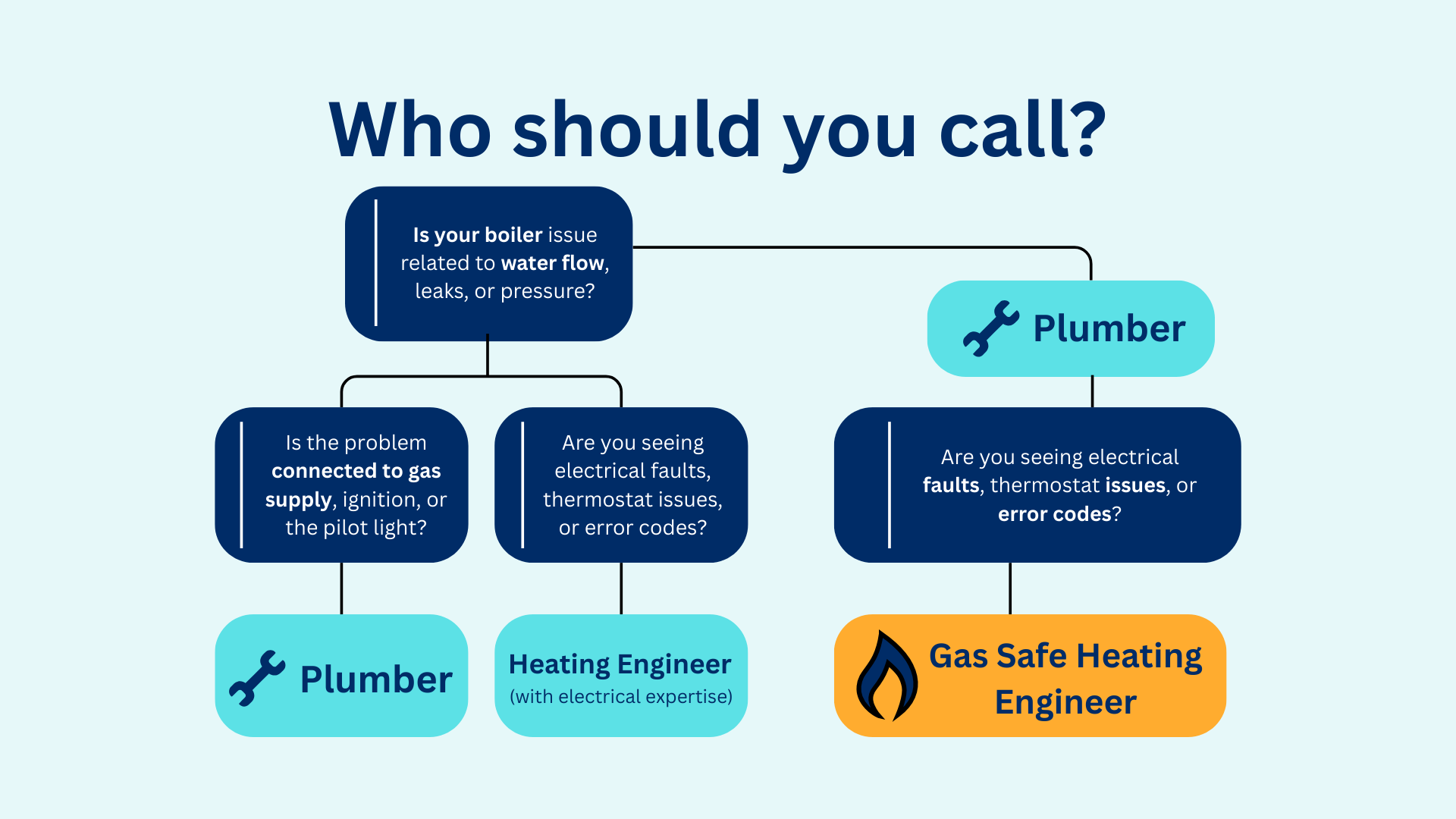

Here's the straightforward answer: Plumbers can fix many boiler-related problems, but only those that don't involve gas components. If the issue relates to water pressure, circulation, electrical components, or external plumbing connections, a qualified plumber can resolve it efficiently and cost-effectively. However, any work involving gas components, internal boiler parts, or safety systems requires a Gas Safe registered engineer by law.

This comprehensive guide explains exactly when a plumber can help with your boiler problems, what requires Gas Safe expertise, realistic repair costs, and how to avoid costly mistakes when choosing the right professional for your heating emergency.

Quick Answer: Yes, plumbers are qualified to handle water-related heating system problems that don't involve gas components. Understanding this distinction can save significant money and time during heating emergencies while ensuring legal compliance and safety.

According to Gas Safe statistics, approximately 40% of emergency boiler call-outs are actually heating system issues that qualified plumbers can resolve without requiring expensive Gas Safe intervention. These water-related problems include pressure issues, circulation failures, external pipe leaks, and electrical components that don't interface with gas systems.

Professional plumbers bring essential expertise for heating system diagnosis and repair, particularly for problems affecting water circulation, pressure regulation, and system integration. However, legal requirements strictly prohibit anyone without Gas Safe registration from working on gas components, regardless of their plumbing qualifications.

What Is the Role of a Plumber in Boiler System Repairs?

Water System Expertise

Qualified plumbers possess comprehensive knowledge of heating water systems that enables them to diagnose and resolve many boiler-related problems effectively. Their expertise encompasses water pressure regulation, circulation system troubleshooting, and integration between boiler systems and household plumbing infrastructure. Plumbers bring similar water system expertise to other appliance installations, like dishwasher setup.

Water pressure problems represent one of the most common heating system issues that plumbers can resolve efficiently. Low system pressure typically indicates water loss somewhere in the heating circuit, air ingress, or failing pressure relief valves. Plumbers understand how to systematically identify pressure loss sources, implement appropriate repairs, and restore optimal system pressure without compromising safety or performance.

Circulation system failures often manifest as uneven heating, cold radiators, or poor hot water performance despite the boiler operating correctly. Professional plumbers can diagnose pump failures, identify circulation blockages, and implement solutions that restore proper water flow throughout heating systems.

Electrical Component Repairs

Many heating system electrical components fall within plumbing expertise when they don't interface directly with gas safety systems. Qualified plumbers can diagnose and repair thermostat problems, timer malfunctions, and basic control system failures that affect heating performance without compromising gas safety requirements.

Thermostat and control system diagnostics require understanding of heating system operation and electrical troubleshooting skills that experienced plumbers develop through training and practical experience. Pump and valve electrical connections represent another area where plumber expertise applies effectively, including heating circulation pumps, zone valves, and diverter valves.

However, electrical work involving gas safety systems, ignition components, or flue monitoring requires Gas Safe qualification due to their direct relationship with combustion safety.

What Boiler Problems Can Plumbers Fix?

Professional plumbers can address several categories of heating system problems that don't involve gas components, often resolving issues that appear to be major boiler failures but actually result from water system problems.

Low water pressure represents the most common repairable issue, typically caused by minor leaks, air accumulation, or system expansion problems. Plumbers use specialized equipment to test system integrity, locate hidden leaks, and determine whether pressure loss results from minor maintenance issues or more significant system problems.

Circulation system problems create symptoms that closely mimic boiler failures but actually result from water movement issues within heating circuits. These typically involve pump failures, blockages, or air accumulation that prevent proper heat distribution. Professional diagnosis can distinguish between pump-related problems, system blockages from accumulated debris, and air accumulation requiring systematic removal.

External plumbing connections outside the boiler cabinet often develop leaks or other problems that affect overall system performance. These include pipe joints, valve assemblies, and interface points with household plumbing systems that fall within standard plumbing expertise.

When Do You Need a Gas Safe Engineer?

Legal requirements strictly mandate Gas Safe registration for any work involving gas supply systems, combustion components, or safety systems within boiler installations. These regulations protect public safety by ensuring qualified professionals handle potentially dangerous gas work.

Internal boiler components including heat exchangers, gas valves, ignition systems, and combustion chambers require Gas Safe expertise due to their direct involvement with gas combustion processes. Gas supply modifications, new installations, and safety system testing also mandate Gas Safe registration under current UK regulations.

Annual boiler safety inspections represent a legal requirement for landlords and recommended practice for homeowners to ensure continued safe operation and maintain manufacturer warranties. Carbon monoxide detection and flue integrity testing require specialized equipment and knowledge that only Gas Safe engineers possess.

Gas Safety (Installation and Use) Regulations mandate Gas Safe registration for all gas work, with significant penalties for non-compliance including unlimited fines and imprisonment. Insurance implications of non-compliant gas work include policy invalidation and personal liability for resulting damage or injury.

Need a plumbing professional?

Get instant quotes from 3-5 vetted local tradespeople. Compare prices, reviews, and availability—all in one place.

Professional Repair Costs in the UK

Understanding realistic cost expectations for heating system repairs helps homeowners budget appropriately while recognizing value provided by professional intervention compared to potential risks from inappropriate professional selection. Use our plumber cost calculator to estimate boiler repair costs in your area.

Simple water system repairs typically cost between £80-£200, covering pressure problems, minor leak repairs, and basic circulation issues that experienced plumbers can resolve quickly. Moderate complexity repairs involving component replacement or extensive diagnostic work generally range from £180-£450, while complex repairs requiring multiple components or extensive system work typically cost £400-£1,000 or more.

Emergency call-out charges substantially increase repair costs, particularly during weekends, holidays, or outside normal working hours when professional availability becomes limited. Emergency rates can double or triple standard repair costs, making appropriate professional selection critical for cost management.

Regional pricing variations significantly impact repair costs across different UK areas:

- London and Southeast: 20-30% premium over national average

- Major cities: 10-20% premium over national average

- Rural areas: Standard pricing with possible travel charges

- Northern regions: 5-10% below national average

The cost comparison demonstrates clear value in professional intervention: plumber repairs typically cost £80-£200 for water system problems versus £300+ for unnecessary Gas Safe call-outs, while DIY mistakes can result in thousands in damage costs plus legal penalties. Compare regional plumber rates to understand pricing in your area.

Types of Boiler Problems

Water Pressure Related Issues

Low system pressure represents one of the most common heating system problems that qualified plumbers can address effectively. Pressure problems typically result from minor leaks, air accumulation, or system expansion issues that create apparent boiler failures but actually require water system expertise.

Modern combi boilers typically operate at pressure between 1-2 bar when cold, with slight increases during heating cycles. When pressure drops below 1 bar, boilers often shut down automatically to protect internal components from damage. Learn more about water pressure problems and solutions if this is a recurring issue in your heating system. This safety feature frequently causes homeowners to assume major boiler failures when the actual problem requires simple pressure restoration.

Diagnostic procedures involve systematic pressure testing, leak detection, and system integrity assessment to identify root causes while distinguishing between minor maintenance issues and more significant problems. Professional plumbers use manometers and pressure testing equipment to accurately measure system pressure and identify leak locations that may not be immediately visible.

Common pressure loss causes include radiator valve weeping, pipe joint deterioration, and automatic air vent operation during temperature fluctuations. Expansion vessel failures can also create pressure irregularities, though these typically require component replacement rather than simple pressure adjustment.

Repair approaches include leak repairs, system repressurization, air removal, and component replacement using appropriate techniques that restore optimal pressure levels. Professional repressurization involves careful water addition through filling loops while monitoring pressure gauges to prevent over-pressurization that could damage system components.

Circulation System Failures

Heating circulation problems create symptoms that closely mimic boiler failures but actually result from water movement issues within heating circuits. These issues typically involve pump failures, blockages, or air accumulation that prevent proper heat distribution throughout properties.

Circulation pump problems manifest in various ways, from complete pump failure causing no heating to reduced pump performance creating uneven temperature distribution. Older pumps may develop bearing wear, impeller damage, or electrical connection problems that affect performance without complete failure. Modern variable speed pumps can also experience electronic control failures that require specialized diagnostic equipment.

System blockages result from accumulated debris, corrosion products, or scale deposits that restrict water flow through heating circuits. Magnetite buildup from internal corrosion creates black sludge that settles in low points and restricts circulation. Scale formation in hard water areas can narrow pipe internal diameters, reducing flow rates and creating apparent heating performance problems.

Professional blockage removal requires specialized techniques and equipment that restore proper circulation while preventing damage to system components during cleaning procedures. Power flushing equipment uses chemical cleaning agents and high-velocity water flow to dislodge accumulated debris. Magnetic filtration systems can be installed to prevent future magnetite circulation through heating circuits.

Air accumulation within heating systems creates circulation problems that often worsen over time as air pockets expand and restrict water flow. Professional air removal involves systematic bleeding procedures throughout entire heating circuits, including less accessible areas like underfloor heating manifolds and high-point air vents that homeowners might overlook.

Electrical System Problems

Heating system electrical components often develop problems that affect overall system performance without involving gas safety systems directly. Timer and programmer problems affect heating schedules and automatic operation without compromising gas safety systems, requiring electrical diagnostic skills and understanding of heating control systems.

Thermostat malfunctions can create apparent heating control problems ranging from complete heating failure to erratic temperature control. Room thermostats may develop calibration drift, internal component failures, or wiring connection problems that affect heating system operation. Modern programmable thermostats include complex electronic circuits that can develop software glitches or memory failures affecting programmed heating schedules.

Zone valve systems used in multi-zone heating installations frequently experience electrical actuator problems that prevent proper water flow distribution. These motorized valves control heating flow to different property areas and may develop position sensing problems, motor failures, or electrical connection issues that create uneven heating distribution.

Professional electrical diagnosis ensures proper problem identification while maintaining safety standards throughout repair procedures. Qualified plumbers use multimeters and specialized testing equipment to diagnose electrical component failures while understanding heating system integration requirements that affect overall performance.

Ready to hire a trusted plumbing?

Compare quotes, read verified reviews, and hire with confidence. Our platform connects you with local professionals who are ready to help.

Instant Quotes

Responses within 24 hours

Verified Reviews

Real customer feedback

No Commitment

Choose when you're ready

However, any electrical work involving gas safety systems requires Gas Safe qualification. This includes ignition system components, flame sensing circuits, and safety interlock systems that directly affect combustion processes and occupant safety.

Common Boiler Problem Symptoms

Understanding boiler problem symptoms helps homeowners communicate effectively with professionals while determining appropriate response urgency. Many symptoms appear serious but actually indicate repairable problems rather than major system failures requiring expensive intervention.

No heating or hot water represents the most concerning symptom but can result from various causes ranging from simple thermostat problems to major component failures. Complete system shutdown often triggers built-in safety systems responding to pressure problems, electrical faults, or minor component malfunctions that professional diagnosis can identify and resolve efficiently.

Unusual noises including banging, whistling, or gurgling sounds typically indicate air accumulation, circulation problems, or scale buildup rather than dangerous internal damage. Banging noises often result from air pockets moving through heating circuits, while whistling may indicate restricted water flow through partially blocked components. Gurgling sounds frequently suggest air entrainment requiring systematic bleeding procedures.

Pilot light problems in older boiler systems can indicate gas supply issues, thermocouple failures, or draft problems affecting combustion stability. However, many pilot light problems actually result from external factors like blocked flues, insufficient gas pressure, or electrical supply problems that don't require internal boiler component replacement.

Radiator heating problems including cold spots, uneven temperatures, or complete radiator failure often suggest circulation or air problems rather than boiler component failures. Individual radiator problems frequently indicate local issues like valve failures, air accumulation, or internal blockages that can be resolved without boiler intervention.

Error codes displayed on modern digital boilers provide specific diagnostic information that helps professionals identify problem areas quickly. Common error codes relate to pressure problems, ignition failures, or sensor malfunctions that may require component replacement but don't necessarily indicate major system problems requiring complete boiler replacement.

Emergency Boiler Repair Procedures

Emergency heating situations require rapid professional assessment to determine appropriate intervention while ensuring occupant safety and preventing additional system damage. Emergency assessment procedures distinguish between genuine safety risks and inconvenient but non-dangerous heating system problems.

Safety priority evaluation includes gas leak detection, carbon monoxide risk assessment, and electrical safety verification to ensure immediate occupant safety. System status determination involves rapid evaluation of heating system condition, boiler operation, and overall system integrity.

Immediate safety procedures take precedence over repair considerations during emergency situations. Gas leak protocols require utility service shutdown, property evacuation, and emergency service notification before any repair work can commence safely. Emergency services (0800 111 999) are required for gas smells, carbon monoxide alarm activation, complete heating failure in sub-zero weather with vulnerable occupants, and major water leaks threatening electrical systems.

Life safety considerations take absolute priority during emergency heating situations, with vulnerable occupants, extreme weather conditions, and potential health risks establishing immediate response requirements regardless of repair complexity or professional availability.

DIY vs Professional Considerations

Limited maintenance activities fall within homeowner capabilities while avoiding legal restrictions and safety risks associated with gas component work. System pressure monitoring involves regular pressure gauge checks and basic understanding of normal operating ranges, enabling homeowners to identify pressure problems early.

Visual inspection procedures help homeowners identify obvious problems including leaks, unusual sounds, or visible component damage that may indicate developing issues requiring professional attention. Basic troubleshooting includes simple reset procedures, thermostat checks, and power supply verification.

When a boiler goes wrong, it’s important to know which tasks you can safely try yourself and which require a qualified professional.

Safe DIY Checks:

- ✅ Check system pressure: Most boilers work best between 1.0–1.5 bar. If it’s low, you may be able to top it up using the filling loop.

- ✅ Bleed radiators: Cold spots in radiators can often be fixed by bleeding air out with a radiator key.

- ✅ Reset the boiler: Many modern boilers have a reset button for temporary faults.

Leave to the Professionals:

- ❌ Gas supply issues: If your boiler won’t ignite or the pilot light keeps going out, only a Gas Safe engineer can investigate safely.

- ❌ Leaks inside the boiler unit: Water leaks from internal seals or valves need professional tools and parts.

- ❌ Electrical faults: Wiring, thermostats, or circuit board problems should only be handled by trained engineers.

- ❌ Flue and ventilation problems: Poor flue installation or blockages can be life-threatening if not fixed by an expert.

Rule of thumb: If the issue involves water circulation or system pressure, a plumber may be able to help. If it touches anything gas-related, you must use a Gas Safe registered engineer.

Choosing the Right Professional

Professional Qualifications and Credentials

Gas Safe registration represents the fundamental legal requirement for gas component work, with specific appliance categories determining individual engineer capabilities for different types of heating equipment. The Gas Safe register maintains detailed records of engineer qualifications, including specific appliance types they're certified to work on. Boiler work typically requires CCN1 (core gas safety) plus CPA1 (gas appliances) qualifications as minimum standards.

Plumbing qualifications including City & Guilds Level 2 Diploma in Plumbing Studies and NVQ Level 2 in Plumbing and Heating demonstrate technical competence for water system work and general heating system maintenance. These qualifications ensure understanding of UK water regulations, system design principles, and safe working practices for heating system components.

Dual-qualified professionals holding both plumbing and Gas Safe credentials offer significant advantages for boiler-related problems. These professionals can diagnose whether problems require gas work or water system intervention, potentially saving customers money through accurate initial assessment and appropriate repair approaches.

Insurance coverage requirements include public liability insurance minimum £2 million and professional indemnity coverage that protect customers from potential claims arising from repair work complications. Adequate insurance coverage ensures financial protection and demonstrates professional commitment to customer safety and service quality.

Professional association membership with organizations like the Chartered Institute of Plumbing and Heating Engineering (CIPHE) or Institute of Domestic Heating and Environmental Engineers (IDHEE) indicates ongoing professional development and commitment to industry standards. These associations provide continuing education and technical updates that maintain professional competence.

Selection Criteria and Evaluation Process

Experience assessment involves evaluating professional track records with similar repair problems and heating system types, ensuring appropriate technical expertise and practical knowledge for specific repair requirements. Specialists with extensive boiler experience often diagnose problems more efficiently while understanding manufacturer-specific requirements that affect repair approaches.

Local knowledge provides advantages for emergency situations and ongoing service relationships. Local professionals understand regional water conditions, common system types, and local supplier networks that can affect repair timeframes and parts availability during heating emergencies.

Customer feedback evaluation through verified reviews and testimonials provides insight into professional service quality, reliability, and customer satisfaction levels. Recent reviews offer more relevant information about current service standards, while consistent positive feedback across extended periods indicates reliable professional performance.

Pricing transparency and detailed quotation procedures indicate professional business practices and customer service orientation. Professional quotes should itemize labor rates, parts costs, travel charges, and additional fees while providing clear timescales for completion and warranty terms for work performed.

Response time capabilities determine professional suitability for urgent repair requirements while establishing realistic expectations for service scheduling during peak demand periods. Emergency response availability and out-of-hours service provision provide important protection during critical heating system failures.

Quality Assurance and Service Standards

Service quality indicators include professional presentation, equipment quality, warranty provision, and emergency response capabilities. These factors typically correlate with technical competence and reliable service provision while providing important customer protection during heating emergencies.

Professional presentation includes clean uniforms, properly marked vehicles, and organized equipment that suggests systematic approach to work and customer service priorities. Well-maintained equipment and tools indicate investment in service quality while providing confidence in professional capabilities.

Warranty provision demonstrates professional confidence in work quality while providing customer protection and ongoing support following repair completion. Standard warranty periods typically range from 12 months for labor to manufacturer warranty pass-through for component replacements.

Follow-up service availability and ongoing maintenance relationships provide long-term value through continued professional support and system optimization. Professionals offering annual service contracts often provide priority response during emergencies while maintaining detailed service records that support efficient future repairs.

Communication skills and customer education demonstrate professional commitment to customer satisfaction and understanding. Quality professionals explain problems clearly, provide maintenance advice, and ensure customers understand system operation and basic troubleshooting procedures that can prevent future emergencies.

Maintenance and Long-term Care

Regular heating system maintenance prevents many emergency repairs while extending equipment lifespan and maintaining optimal performance throughout heating seasons. Annual professional inspections identify developing problems before they become emergency situations while ensuring continued safe operation and regulatory compliance.

System optimization procedures including balancing, cleaning, and component adjustment maintain peak performance while identifying upgrade opportunities that improve efficiency and reduce operating costs. Performance monitoring and trend analysis help identify gradual system deterioration that indicates developing problems requiring professional attention.

Component lifecycle management involves tracking equipment age, performance trends, and replacement scheduling to optimize system reliability while managing repair and replacement costs effectively. Strategic component replacement prevents emergency failures while maintaining system performance throughout heating seasons.

Professional Expertise Protects Your Investment

Understanding when plumbers can help with boiler problems versus when Gas Safe engineers are required enables informed decisions that save money while ensuring safety and legal compliance. Professional expertise provides optimal problem resolution while protecting customers from risks associated with inappropriate repair attempts.

Investment in professional heating system service pays long-term dividends through improved reliability, maintained warranty coverage, regulatory compliance, and avoided emergency repair costs. Professional maintenance and timely intervention prevent most heating emergencies while ensuring continued safe operation throughout equipment lifespan.

Ready to resolve your heating problems professionally? FixaTrader connects you with qualified local professionals who can diagnose whether your boiler needs plumber or Gas Safe intervention. Compare quotes from verified professionals, read genuine customer reviews, and book with confidence knowing your heating system receives appropriate expert attention.